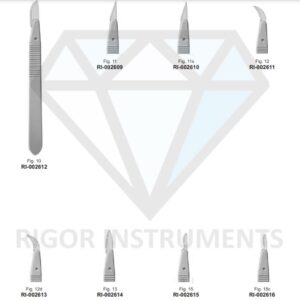

Scalpel Handles (RI-002605)

Scalpel handles are essential surgical instruments used by medical professionals to hold and control the surgical blades during various procedures. These handles play a crucial role in achieving precision and accuracy during surgeries.Scalpel handles are indispensable tools in the field of surgery. Their sturdy construction, ergonomic design, and versatility make them essential instruments for medical professionals. With various types to choose from, surgeons can select the most appropriate scalpel handle for each surgical procedure, enabling precise control, safety, and optimal surgical outcomes.

Detailed Description

Technical Specifications

Packaging and Shipping

Related Products

Reviews

Detailed Description

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Technical Specifications

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Packaging and Shipping

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Related Products

Related products

-

Sale!

Resection Knives (RI-002646)

$42.00Original price was: $42.00.$39.00Current price is: $39.00. View More -

Scalpel Handle # 7 (RI-S-1008)

View More -

Sale!

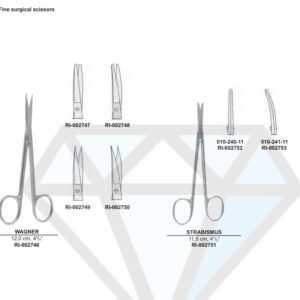

Fine Surgical Scissors (RI-002746)

$9.00Original price was: $9.00.$8.00Current price is: $8.00. View More -

Sale!

Disposable Scalpels (RI-002612)

$8.00Original price was: $8.00.$7.00Current price is: $7.00. View More

Reviews

Reviews

Add a review

Be the first to review “Scalpel Handles (RI-002605)” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.