Importance of Hole Punching in Surgical Instruments Manufacturing

Hole punching, is a critical process in the production of surgical instruments, especially those that require assembly, fastening, drainage, or precision alignment. hole punching involves creating accurately sized and placed holes in stainless steel components using mechanical or hydraulic punch presses.

Why Hole Punching Matters

1. Assembly & Fastening

Holes are used to join multiple parts with rivets, screws, or pins.

Crucial in instruments like scissors, forceps, rongeurs, where pivot points and joints are needed.

2. Drainage & Cleaning

Some surgical tools (e.g. cannulas, retractors) have drainage holes to allow fluid flow or for sterilization access.

Promotes hygiene, prevents fluid retention, and supports efficient autoclaving.

3. Ergonomics & Weight Reduction

Holes are sometimes added to reduce instrument weight without compromising strength.

Enhances handling comfort for surgeons during long procedures.

4. Precision & Alignment

Accurately punched holes ensure exact alignment during:

Assembly of multi-part tools

Mounting on surgical trays or racks

Integration with other surgical systems

5. Instrument Functionality

Some instruments like biopsy punches or skin punch tools rely directly on the punched hole itself for their medical function.

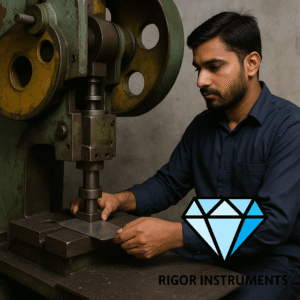

Hole Punching Methods at Rigor Instruments

Hydraulic Punch Presses – For high-strength stainless steels (420, 440C, 316L)

CNC-Controlled Punching – For precision and consistency in complex designs

Custom Dies & Molds – Tailored for specific instrument models

What Happens If Hole Punching Is Poor?

| Issue | Consequence |

|---|---|

| Misaligned holes | Poor assembly, loose joints |

| Rough or uneven edges | Increased infection risk, poor sterilization |

| Inconsistent hole sizes | Assembly failure, mechanical weakness |

| No drainage holes | Fluid retention, contamination risk |

Rigor Instruments – Key Expertise in Hole Punching

At Rigor Instruments, hole punching is not just a process — it’s a precision-driven skill that plays a vital role in the structural integrity and functionality of surgical tools. Our expertise ensures every punched hole meets strict tolerance, alignment, and surface finish standards required in surgical environments.

🛠 Our Strengths in Hole Punching

High-Precision CNC Punching

We use automated CNC punch presses for unmatched accuracy

Tolerance control up to ±0.05 mm

Suitable for high-grade steels like 420, 440C, 17-4 PH, and 316L

Custom Tooling & Dies

In-house designed dies for customized hole shapes and placements

Supports both round, oval, and slotted holes

Essential for instrument joints, drain holes, and ergonomic designs

Hydraulic & Mechanical Punching Lines

Dedicated machines for both sheet and rod-based blanks

Handles various material thicknesses from 0.5 mm to 10 mm

Integrated Process Flow

Hole punching is seamlessly integrated with shearing, forging, and machining

Ensures perfect alignment and positioning in multi-step assemblies

Quality & Finish

Each punched component undergoes deburring and polishing

Clean edges ensure zero contamination, easy sterilization, and long tool life