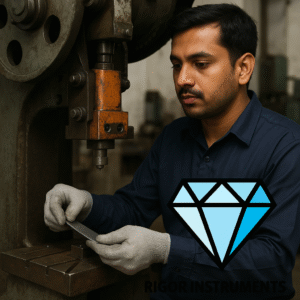

Stamping Process in Surgical Instruments Manufacturing

Stamping is a key metalworking process in the surgical instrument industry that involves shaping or forming stainless steel sheets or blanks into precise components using dies and high-pressure presses. It’s used to create consistent shapes, markings, and detailed contours required for functionality and brand identity.

Why Stamping is Important

Shape Formation

Converts flat stainless steel into 3D instrument components (e.g. retractor blades, scissor handles)

Allows mass production with high precision and repeatability

Part Number & Logo Marking

Used to stamp model numbers, sizes, “CE” marks, or “RIGOR INSTRUMENTS” branding directly on the tools

Ensures traceability, compliance, and professional finish

Structural Integrity

Precisely stamped parts have uniform thickness and dimensions

Reduces machining time and ensures fit accuracy during assembly

Types of Stamping Used by Rigor Instruments

| Type | Purpose |

|---|---|

| Blanking | Cuts flat metal shapes for further processing |

| Embossing | Adds raised markings/logos on the tool surface |

| Piercing | Makes precision holes and slots during forming |

| Coining | Adds fine text or numerical detail to surface |

| Bending/Forming | Shapes parts like clamps, scissors, retractors |

Stamping in Rigor Instruments Workflow

Die Design – Custom hardened steel dies created for each instrument model

Steel Preparation – 420 or 440C stainless blanks cleaned and aligned

High-Tonnage Presses – Mechanical or hydraulic presses apply up to 100+ tons force

Marking – CE, LOT numbers, sizes, or RIGOR branding stamped

Finishing – Deburring, polishing, and quality control

Risks of Poor Stamping

| Issue | Result |

|---|---|

| Misaligned stamps | Tools won’t fit or assemble properly |

| Weak embossed marks | Fades during sterilization or use |

| Burrs or rough edges | Risk of infection, discomfort, or contamination |