Importance of QA (Quality Assurance) Inspection in Surgical Instruments

Quality Assurance (QA) inspection is a critical pillar in the manufacturing of surgical instruments. The QA inspection process ensures that every instrument meets the highest standards of safety, precision, durability, and hygiene before it reaches surgeons and patients, epitomizing the importance of thorough QA Inspection.

1. Patient Safety

Instruments come into direct contact with human tissue, blood, and organs.

A defect—even as small as a misaligned jaw or a burr—can cause:

Internal injury

Infections

Surgical complications

2. Surgical Performance

QA ensures the instrument performs its intended function flawlessly.

Scissors must cut cleanly

Forceps must grip firmly

Clamps must lock securely

High precision minimizes surgeon fatigue and increases procedure success.

3. Regulatory Compliance

Instruments must comply with ISO 13485, CE marking, and FDA standards.

Regular inspections verify documentation, tolerances, and material conformity.

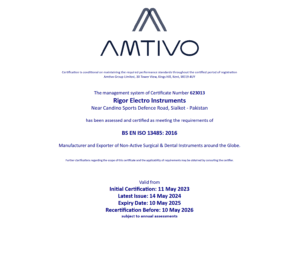

Certified QA Guidelines According to ISO 13485:2016

ISO 13485 is the international quality management system standard for medical devices, including surgical instruments. It outlines strict QA protocols to ensure safety, performance, and regulatory compliance across all stages of production.

Core QA Requirements Under ISO 13485

| Section | Requirement |

|---|---|

| 4.2 – Documentation | Maintain complete Quality Manual, procedures, records, device master file |

| 6.2 – Competency | Ensure QA personnel are trained, certified, and records are maintained |

| 7.1 – Risk Management | Identify and control risks throughout the product lifecycle |

| 7.4 – Supplier Controls | Approve and monitor raw material suppliers (e.g., steel vendors) |

| 7.5 – Production Control | Validate every critical process (forging, polishing, assembly, etc.) |

| 7.6 – Inspection Equipment | Calibrate and maintain measuring tools (calipers, gauges, spectrometers) |

| 8.2 – Product Inspection | Perform in-process and final inspections, record non-conformities |

| 8.3 – Nonconformance | Segregate defective instruments and initiate corrective/preventive action |

| 8.5 – CAPA System | Maintain Corrective and Preventive Action program with root cause analysis |

Key QA Activities Required by ISO 13485

Incoming Inspection

Raw stainless steel checked for grade (420, 440C, 316L)

Chemical composition verified via spectrometer

In-Process Inspection

Measurements during trimming, forging, milling, polishing

Use of digital gauges, templates, and visual inspection under light/magnification

3. Batch-Level QA Inspection

All products are inspected during:

In-process stages (after forging, milling, polishing)

Final inspection before sterilization/packaging

Random or 100% sampling based on risk classification (Class I, IIa, etc.)

Rigor’s 3 step Finish Instruments Formula

Final Inspection

100% piece-by-piece visual and functional inspection

Sharpness test, ring alignment, finish quality, marking check

Glove test (no burrs or edges)

Record Keeping

QA checklists, operator logs, batch traceability (lot numbers, production date)

Internal Audits

Regular audits of QA practices and compliance with documented procedures

Final Product Release (Clause 8.2.6)

Only products approved and documented by authorized QA personnel can be shipped

Must include:

Inspection records

Device history record (DHR)

CE or FDA compliance documentation if applicable

4. Consistency & Traceability

QA tracks instrument batches, lot numbers, and inspection reports.

Ensures consistency across production and traceability in case of product recall.

5. Corrosion Resistance & Clean ability

QA includes surface finish inspection to ensure:

No rust-prone zones

No hidden crevices that could trap bacteria

Polishing is smooth and uniform

Key QA Inspection Areas at Rigor Instruments

| Inspection Point | Method Used |

|---|---|

| Dimensional Accuracy | Digital calipers, micrometers, gauges |

| Functionality Testing | Opening/closing force, blade sharpness test |

| Surface Finish Check | Visual, magnifying lens, glove sensitivity test |

| Material Verification | Spectrometer test for steel grade confirmation |

| Joint Alignment | Ring gauge, jaw fit test |

| Sterilization Simulation | Autoclave testing and discoloration inspection |

Risks of Skipping Proper QA

| Issue | Result |

|---|---|

| Dull or misaligned blades | Incomplete cuts, tissue tearing |

| Surface burrs or cracks | Infection risk, breakage in body |

| Incorrect material | Rusting, bio compatibility failure |

| Poor joint fitting | Loose or stiff instrument movement |

How Rigor Instruments Ensures Top-Quality QA

100% Hand & Machine Inspection of every instrument

Multi-step QC checkpoints from raw material to final packing

Certified QA inspectors trained under ISO 13485 guidelines

Use of laser marking for full product traceability

Rigor Instruments’ CE QA Commitment

All instruments undergo 100% final inspection before CE-labeled packing

Inspection done under clean-room-like conditions using calibrated tools

Each product batch is tied to a traceable lot number and inspection record

QA team trained in ISO 13485 + MDR (EU) 2017/745 procedures