How to Choose the Right Surgical Scissor for Your Procedure

Rigor Instruments – Precision Cutting, Perfect Control

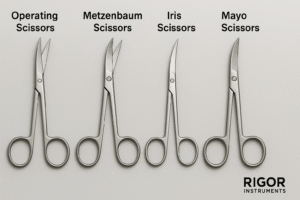

Choosing the correct surgical scissor is critical for tissue preservation, cutting accuracy, and surgical success. The right selection depends on the tissue type, depth, and purpose (cutting vs. dissecting).

1. Based on Function

| Type | Best For | Example Scissors |

|---|---|---|

| Dissecting | Blunt tissue separation | Metzenbaum, Mayo (blunt) |

| Cutting | Cutting sutures, gauze, fascia | Mayo (sharp), Suture Scissors |

| Microsurgical | Precision cuts in ophthalmic/neuro | Castroviejo, Vannas |

2. Based on Tissue Type

| Tissue Type | Recommended Scissor | Tip Type |

|---|---|---|

| Delicate tissue | Metzenbaum Scissors | Blunt tips |

| Tough tissue/fascia | Mayo Scissors (Straight/Curved) | Sharp tips |

| Fine/vascular tissue | Iris, Potts, Castroviejo | Fine-point |

| Sutures | Suture Removal, Spencer | Hooked or notched tips |

3. Based on Scissor Tip

Blunt/Blunt: Safe dissection near sensitive structures

Blunt/Sharp: Versatile; some cutting, some dissection

Sharp/Sharp: Precise cutting, especially on fascia and sutures

4. Curved vs. Straight Blades

| Blade Type | Use Case |

|---|---|

| Straight | Surface-level cutting (sutures, gauze) |

| Curved | Deep dissection and visibility around structures |

5. Handle Style & Mechanism

Ring Handle: Standard for general use

Spring Handle: Ideal for microsurgical or ophthalmic work

Double-action: Used in orthopedic and endoscopic scissors

6. Blade Edge Options

| Edge Type | Use Case |

|---|---|

| Smooth | Clean, precise cuts in soft tissue |

| Serrated | Prevents slipping; ideal for tough tissue |

| Super-cut | One razor edge + one micro-serrated edge for superior cutting power |

7. Material & Finish (Rigor Instruments Standard)

AISI 420 Stainless Steel for hardness

Titanium (on request) for lightweight microsurgical scissors

Matte/Satin Finish to reduce glare

Black (Cerakoted) or mirror-polished options for specialty procedures

Quick Reference Examples:

Metzenbaum Curved (Blunt): Ideal for soft tissue dissection

Mayo Straight (Sharp): Great for cutting fascia

Spencer Scissors: Designed for suture removal

Castroviejo Scissors: Microsurgical precision cutting

SuperCut Mayo: Powerful, no-slip cutting in orthopedic procedures

Lets Walk you Through The Final Checking Department of Rigor

Rigor Instruments – Precision You Can Trust

Surgical scissors are critical tools used across every specialty—whether it’s dissecting delicate tissues or cutting tough fascia. Ensuring their quality, performance, and safety is vital for successful outcomes in the operating room. At Rigor Instruments, every pair of scissors undergoes a multi-step inspection to meet international standards like ISO 13485 and CE certification.

Here’s a comprehensive guide on how to check the quality of surgical scissors—useful for hospitals, distributors, and OEM buyers.

1. Visual Inspection

A thorough visual examination is the first step in quality assurance:

Check for surface defects: Look for scratches, pits, dents, or signs of rust.

Blade alignment: The tips should meet precisely, with no visible gap or misalignment.

Symmetry: Both arms of the scissors should be mirror images and open evenly.

2. Blade Sharpness Test

Sharpness directly impacts cutting performance:

Use a latex glove or gauze test: Scissors should cut through smoothly without snagging.

In high-quality scissors like those from Rigor, cutting action should require minimal force.

3. Joint Movement & Tension

The joint (screw or rivet) is the heart of the instrument:

Open and close the scissors 10–15 times. Movement should be smooth and free from resistance or looseness.

No clicking sounds or “wobble” should be felt.

Tension should be appropriate—not too tight or too loose.

4. Material Verification

Most surgical scissors are made from:

AISI 420 (Martensitic Stainless Steel) for sharpness and strength

AISI 316L (Austenitic Stainless Steel) for corrosion resistance

Titanium for microsurgical applications

A magnetism test helps verify the material:

420 steel is mildly magnetic;

316L and titanium are non-magnetic.

5. Corrosion Resistance Test (Optional but Critical)

High-grade scissors should resist corrosion under harsh sterilization cycles:

Soak in 6% Ferric Chloride for 90 minutes, then rinse and inspect.

No discoloration, pitting, or rust should appear.

Rigor Instruments scissors pass internal salt spray and ferric chloride testing.

6. Finish Quality

Scissors should have a consistent and clean surface:

Matte/satin finish: Reduces glare in the OR

Mirror polish: Enhances corrosion resistance and ease of cleaning

Black finish (cerakoted or ebonized): Ideal for laser or microsurgery

Ensure the finish is uniform with no flaking, irregular patches, or discoloration.

7. Blade Type & Serration Check

Smooth edge scissors: Ideal for soft tissue

Serrated edge: Prevents tissue slippage—especially for fascia or tendons

SuperCut blades: Combine a razor edge with micro-serrations for ultimate cutting performance

Run your fingertip (carefully) or a soft cloth along the blade to feel serrations.

8. Marking & Traceability

High-quality instruments will have:

Laser-etched branding (e.g., “RIGOR”)

Lot number or batch code

CE, ISO 13485, or FDA marks (if required)

Poor-quality instruments may have ink markings or inconsistent etching.

9. Packaging Inspection

Check that each scissor is:

Packed in sterile or non-sterile medical-grade pouches

Free from dust or particles inside the pouch

Labeled properly with size, type, and reference number

Rigor Instruments Quality Promise

All Rigor Instruments scissors undergo:

Precision CNC milling & hand-finishing

Electropolishing & passivation

Ultrasonic cleaning & drying

Final QA by ISO-trained inspectors

Whether you’re sourcing for hospitals, distributors, or private-label OEMs, we guarantee reliability, sharpness, and performance.

Need samples or custom QA reports?

Email us at: [email protected]

📞 Call/WhatsApp: +92 303 7759000