Rigor Instruments’ Clean Room: Specifications & Compliance

Ensuring Sterile Precision for World-Class Surgical Instruments

At Rigor Instruments, we understand that the final phase of surgical instrument manufacturing—cleaning, inspection, and packaging—must meet the highest global standards. That’s why we operate a state-of-the-art clean room, designed to ensure absolute sterility, precision, and compliance with international regulatory norms.

Clean Room Overview

| Feature | Specification |

|---|---|

| Clean Room Class | ISO 7 (Class 10,000) |

| Total Area | 300 square feet (expandable to 600 sq. ft.) |

| Usage | Final inspection, ultrasonic drying, and medical-grade packaging |

| Filtration | HEPA filters (99.97% @ 0.3 micron) |

| Air Changes per Hour | 60–90 ACH |

| Temperature Control | 21–23°C (maintained) |

| Humidity Control | 45–55% RH |

| Lighting | 500 lux anti-glare, sterile-grade lighting |

| Surfaces | Anti-microbial epoxy flooring, stainless steel benches |

| Staff Protocol | Full gowning (coveralls, gloves, shoe covers, masks, hair nets) |

| Monitoring | Digital particle counter, pressure monitoring, and access control |

Compliances Met

ISO 13485:2016 – Medical device manufacturing quality management

ISO 14644-1 – Cleanroom classification

CE Marking Packaging Requirements

US FDA 21 CFR Part 820

Clean Room Activities

Post-ultrasonic drying

Visual and magnified inspection

Laser marking

Packaging into sterile barrier systems

Final sealing and batch coding

Why Our Clean Room Sets Us Apart

Many manufacturers in Pakistan skip this step or outsource packaging to third parties. At Rigor Instruments, our in-house clean room guarantees:

Full traceability

Zero bioburden

Sterility protection

Better client and regulatory confidence

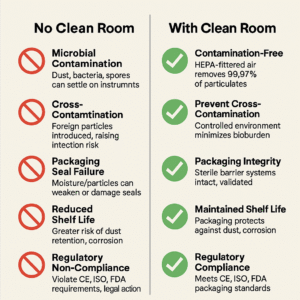

The Hidden Risks of Skipping Clean Room Packaging in Surgical Instruments

Why Rigor Instruments Invests in Sterile Environments—So Patients Don’t Pay the Price

Final packaging is not just a formality—it is the last line of defense between a surgical instrument and the patient. Skipping a controlled clean room during this process exposes both healthcare professionals and patients to serious risks.

Here’s what’s at stake when instruments are not packed in ISO-compliant clean rooms:

1. Microbial Contamination

Without HEPA-filtered air and controlled environments:

Dust, bacteria, and spores can settle on instruments

Contaminated tools can cause post-operative infections, even if they’re sterilized later

Especially dangerous in orthopedic, neurosurgery, or implant procedures

2. Cross-Contamination

Handling instruments in non-clean zones may introduce foreign biological particles, human skin cells, or textile fibers

Can lead to sepsis, delayed wound healing, and even litigation

3. Packaging Seal Failure

In uncontrolled environments:

Moisture and particulate matter can weaken packaging seals

Packaging may fail during sterilization (autoclave or ETO), leading to instrument rejection

Hospitals may unknowingly use non-sterile packs, compromising surgical protocols

4. Reduced Shelf Life

Instruments packed outside clean rooms are more prone to moisture absorption, corrosion, and dust retention

This reduces shelf life, especially for exported or long-storage instruments

5. Regulatory Non-Compliance

CE, ISO 13485, and FDA guidelines require validated cleanroom conditions for Class I/II surgical instruments

Instruments packaged outside cleanrooms may face:

Customs rejection

Loss of tenders

Recall risks

Legal action for negligence

Why Rigor Instruments Always Uses Clean Rooms

We operate a fully equipped ISO 7 clean room with:

HEPA filtration (99.97% purity)

Controlled air pressure, humidity, and temperature

Anti-static, anti-microbial flooring

Proper gowning and trained personnel

Full traceability from sterilization to packaging

This ensures every Rigor instrument is delivered contamination-free, sterile-ready, and globally compliant.

Bottom Line:

If the final packaging is compromised, so is the patient’s safety.

That’s why Rigor Instruments never compromises—and educates clients to recognize the difference.

📩 Want to learn how to audit your current supplier’s packaging standards?

Email us: [email protected]

WhatsApp: +92 303 7759000

🌐 www.rigorinstruments.com