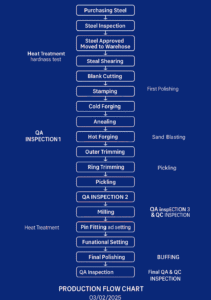

A Glimpse of some processes done to your instrument

At Rigor Instruments, precision is not just a goal — it’s our foundation. Our state-of-the-art manufacturing production process ensures surgical instruments that meet the strictest international standards of ISO 13485, CE marking, and FDA compliance. Here’s a detailed look at how we transform high-quality raw steel into world-class surgical tools.

1. Raw Material Procurement & Inspection

Purchasing Steel: Only medical-grade stainless steel (420, 440C, 316L) is procured from certified suppliers.

Steel Inspection: Chemical composition and hardness are tested.

Approval & Storage: Only approved steel is moved to the warehouse.

2. Primary Processing

Steel Shearing & Blank Cutting: Sheets are sheared and cut into blanks for the desired instrument.

Hole Punching & Stamping: Identification marks and hinge holes are punched using CNC or press machines.

Straightening: Blanks are straightened for dimensional accuracy.

3. Forming & Forging

Cold Forging & Annealing: Increases strength, followed by annealing to reduce brittleness.

Hot Forging: Heats metal for complex shapes and durability.

Outer & Ring Trimming: Removes excess metal for refined shaping.

4. Pickling & First QA

Pickling: Acid bath cleans oxidation and surface contaminants.

QA Inspection 1: Instruments are checked for defects post-forging.

5. Machining & Functional Settings

Milling: Complex grooves and slots are machined.

QA & QC Inspection 2: Tolerances and dimensions are checked.

Pin Fitting & Functional Setting: Joint assembly and mechanical calibration.

QA Inspection 3: Mechanical action is verified.

6. Cleaning & Surface Preparation

Boil Test & Passivation: Instruments are boiled and chemically passivated to enhance corrosion resistance.

Final Polishing: Surfaces are mirror-finished for clinical use.

Ultrasonic Cleaning: High-frequency vibration removes micro-particles.

Sandblasting: Matte finish is applied where required.

7. Surface Coating & Branding

Gold Plating / Plasma Coating: Specialty finishes for ophthalmic or aesthetic tools.

Final Setting & Buffing: Final touches on contours and shine.

QA & QC Final Inspection: All instruments undergo a double-check process.

8. Assembly & Labeling

Grinding & Fitting: Sharpness and mechanical assembly.

Lot Labeling: Each batch is labeled for traceability.

UDI & Barcode Printing: Instruments are marked with unique device identifiers.

9. Packaging & Dispatch

Packaging: Sterile or bulk packaging per customer specifications.

Storage & Shipping: Secure warehousing until delivery.

What Makes Rigor Instruments a Leading Surgical Items Manufacturer in Pakistan?