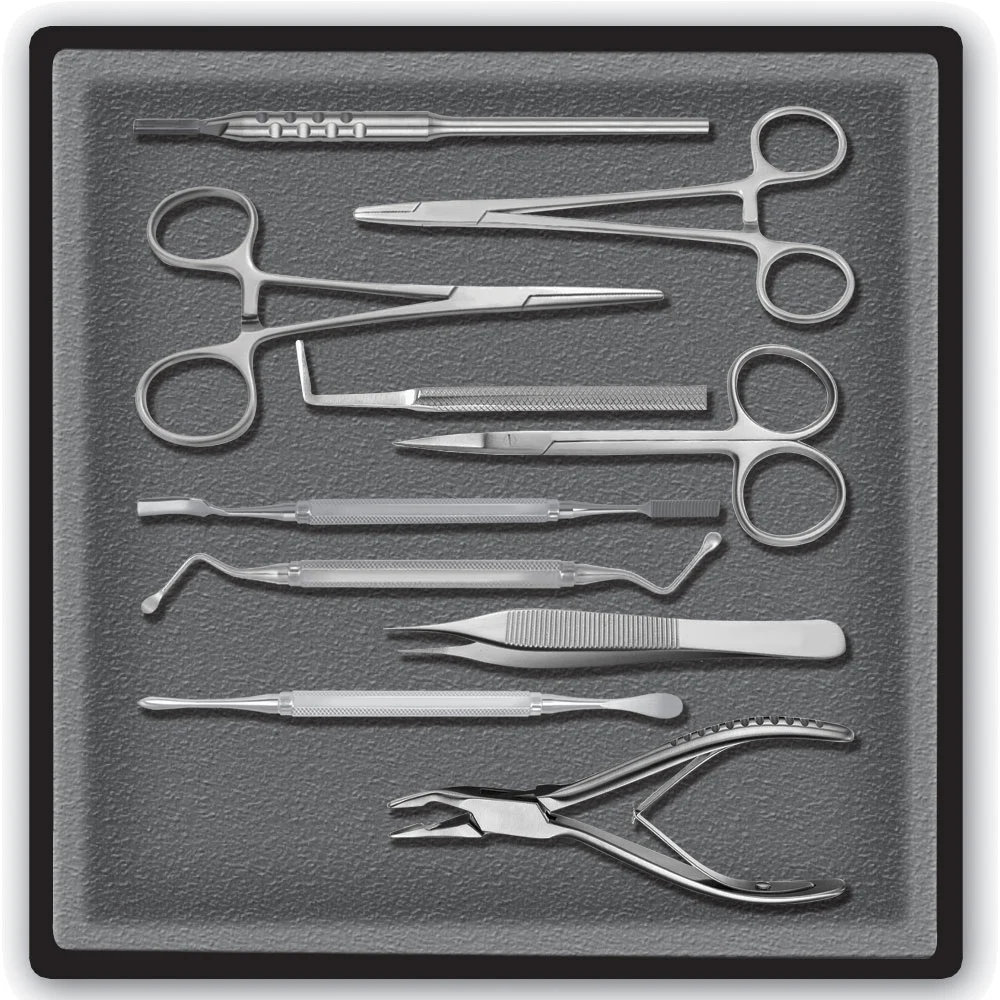

Making dental operations safe and effective depends much on surgical instruments for the mouth. These dental surgical instruments—which range in kind from forceps, scalers, drills, and mirrors—need to be quite dependable and trustworthy so that dental treatments are available safely and precisely.

Not only for the success of dental treatments but also for patients’ safety and satisfaction depend on their dependability and trustworthiness. The factors that make dental surgical tools dependable and trustworthy will be discussed in this handbook. Furthermore, you can study the hazards involved with employing inferior tools to ensure that these instruments satisfy high criteria.

Factors Affecting Reliability and Trustworthiness of Dental Surgical Instruments

Several things affect how reliable and trustworthy dental surgical tools are. These include the materials available, how the manufacturing is perform, medical devices quality in Pakistan, and the rules by regulatory authorities.

Material Used

The materials used to create dental tools significantly affect their lifetime, performance, and safety level as well as their durability. Because it doesn’t rust and keeps sharp for a long period, people frequently prefer premium stainless steel. For dental procedures requiring great accuracy, this is crucial.

To function well, some instruments—such as forceps and scalers—need to remain sharp and not rust. With the correct material, instruments will be able to be sterilised repeatedly without losing their shape.

Manufacturing Process

When making dental tools, accuracy is very important. Computer-aided design and laser cutting are two examples of advanced manufacturing methods that are used to make sure that tools are made exactly as needed. Tools that aren’t made well can lead to serious problems, like muscle damage, pain, and even infections. High manufacturing standards make it less likely for companies to make tools that aren’t up to par, which makes them more reliable.

Checking for Quality

It is very important to have reliable quality control to make sure that dental tools meets the standards before it gets to dentists. Manufacturers usually have strict quality control procedures that include eye checks, functional tests, and sometimes using X-rays or other scanning technologies to find problems inside the product. Regular checks help find and get rid of broken instruments, making sure that dentists only get safe, useful tools.

Sterilization Compatibility

To keep things clean and stop infections, dental tools must be able to be sterilized. Long-term use is more likely to be successful with instruments that can handle the high temperatures and strong chemicals used in autoclaving. Those that break down in these situations could break during procedures or lose their edge, which would make them less useful and possibly dangerous.

Rules and Regulations

Regulatory guidelines set by groups like the Food and Drug Administration (FDA) in the US or the CE marking system in the EU make sure that dental instruments are safe and work well. These standards were made after a lot of testing and review. They add another level of confidence to the dependability and trustworthiness of dental tools. If an instrument doesn’t meet these standards, it could mean that it isn’t effective and could be dangerous.

What are the Common Risks of Unreliable Dental Instruments?

Using dental tools that aren’t dependable or aren’t very good puts both dentists and patients at great risk. Poorly made tools can break down during procedures. This can be painful for the patient and even cause harm. For instance, a drill that gets too hot or a pair of tools that breaks during an extraction can do a lot of damage to the tissues around it. Furthermore, instruments that rust easily or can’t handle being sterilized can get dirty. This will be bringing bacteria into the patient’s body and raising the risk of infection.

When dental professionals use cheap or broken tools, it can also make patients less trusting of their dentist. People who go to the doctor or nurse expect them to use only the best tools to keep them safe. If a patient has a procedure that hurts or needs more work because of broken equipment, they might not trust their dentist anymore, which could hurt the provider’s image.

Conclusion

Reliability and trustworthiness of reliable dental equipment Pakistan are important parts of safe and effective dental care. The materials used, the way they are made, quality control, and making sure they meet government standards are all things that affect how reliable these tools are as a whole.

Poorly made or unreliable instruments can be very dangerous for both patients and dentists. But following strict production and testing procedures can help lower these risks. By constantly buying high-quality tools, following strict rules set by regulators, and doing their jobs well, dentists can give people safe and effective care that makes their experience good.