Mastering Arthroscopy Punches: Types, Surgical Uses & Rigor’s CNC Precision Leadership

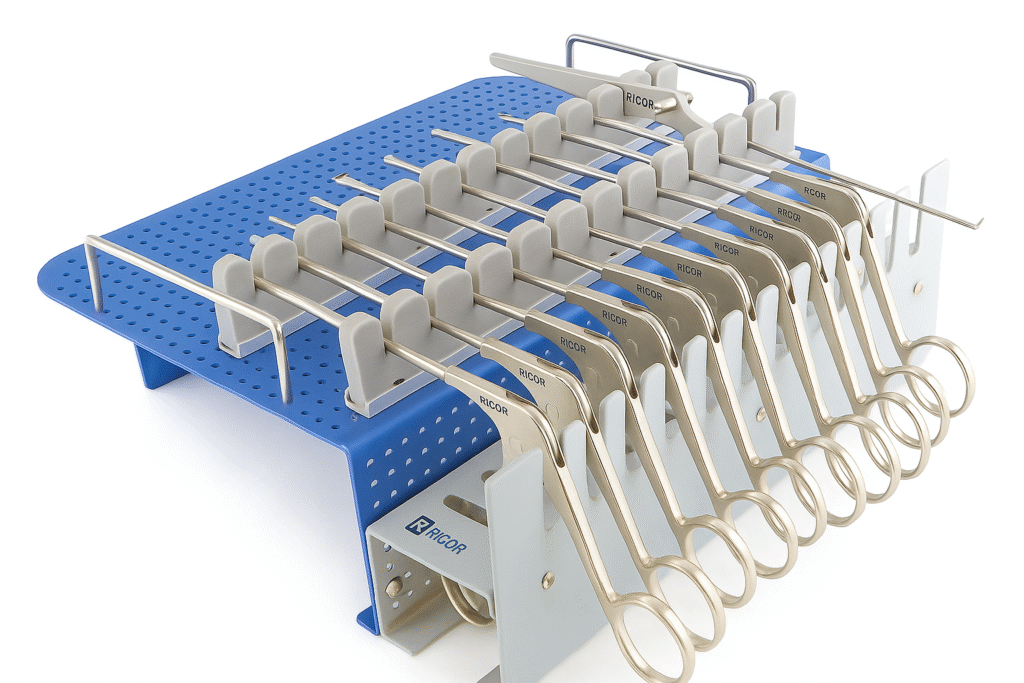

Arthroscopy is a minimally invasive surgical procedure that requires tools of extreme precision—and none more important than the arthroscopy punch. At Rigor Instruments, we have earned our leadership in arthroscopy punch production through a perfect fusion of surgical craftsmanship and CNC machining excellence.

In this article, we’ll explore:

Types of arthroscopy punches

Their applications in different procedures

Why Rigor’s CNC-manufactured punches set new standards globally

What is an Arthroscopy Punch?

An arthroscopy punch is a hand-held surgical instrument designed to cut and remove soft tissues within a joint during arthroscopic procedures. It allows orthopedic surgeons to operate through tiny incisions with maximum accuracy and minimal trauma to the patient.

Common Types of Arthroscopy Punches & Their Uses

1. Up-Bite Punch

Use: Removes tissue from the superior joint space

Common Procedures: Shoulder and knee arthroscopies

Advantage: Excellent access to upper meniscal or labral areas

2. Down-Bite Punch

Use: Targets inferior joint space

Common Procedures: Hip and shoulder scopes

Advantage: Facilitates lower surface tissue removal

3. Straight Punch

Use: General-purpose tissue cutting

Common Procedures: Knee meniscectomies

Advantage: Ideal for mid line work in tight spaces

4. Left/Right Angled Punches

Use: Navigating curved joint anatomy

Common Procedures: Elbow, wrist, and ankle arthroscopies

Advantage: Reaches areas that are anatomically difficult to access

5. Meniscal Punch

Use: Trimming damaged meniscus with precision

Common Procedures: Knee surgeries

Advantage: Protects healthy cartilage while removing only diseased tissue

6. Rotating or All-Directional Punch

Use: Versatile in multi-directional trimming

Common Procedures: Complex labral repairs

Advantage: One tool, multiple access points—enhancing efficiency

Rigor: Pakistan’s Pioneer in Cold Forging for Arthroscopy Punches

Unlike most manufacturers in the region who rely on outdated casting or manual shaping, Rigor Instruments is the only company in Pakistan using precision cold forging for arthroscopy punches—especially remarkable given that these are delicate, handheld instruments requiring micro-level tolerances.

Why Cold Forging Matters in Arthroscopy Punch Manufacturing

Cold forging is a process where metal is shaped at room temperature using high-pressure dies, producing an exceptionally strong, accurate, and dense structure. For handheld instruments like arthroscopy punches, this process offers game-changing benefits:

Key Benefits of Cold Forging at Rigor

Superior Structural Integrity

Cold forging aligns the metal’s grain flow, making the punch stronger and more durable, with fewer chances of failure inside the body.

Consistent Tip Geometry

The punch’s jaw, neck, and shaft dimensions remain perfectly uniform, ensuring consistent cutting performance across all units.

Reduced Material Waste

Compared to machining from solid bars, cold forging optimizes raw material usage, supporting sustainability.

Enhanced Fatigue Resistance

Cold-forged punches withstand repeated sterilization and usage cycles without distortion or micro-cracks.

How Rigor Leads the Way in Machinery & In-House Capabilities

Proprietary Forging Dies & Molds

Rigor has developed custom die sets in-house specifically for arthroscopy punch blanks—a capability no other surgical instrument maker in Pakistan possesses at this level.

In-House Hydraulic & Mechanical Forging Presses

Our forging machines deliver pressures of up to 120 tons, shaping high-grade stainless steel with precision-forming dies to predefine the punch body’s shape.

Integrated CNC Post-Forging Finishing

After forging, each piece is transferred to multi-axis CNC stations, where tip shaping, jaw alignment, and surface finishing are performed without ever leaving our facility.

Skilled Technicians & Toolmakers

A dedicated team of Rigor-trained toolmakers work exclusively on cold-forged punch components, ensuring unmatched consistency.

Pakistan’s First & Only

Rigor is proud to be the first and only company in Pakistan with:

In-house cold forging for micro instruments

Purpose-built CNC + forging integration

End-to-end arthroscopy punch production under one roof

How CNC Technology Sets Rigor Apart

At Rigor Instruments, we deploy state-of-the-art CNC (Computer Numerical Control) machining to achieve unmatched precision in punch manufacturing. Here’s how CNC makes the difference:

Micron-Level Accuracy

Our CNC systems deliver consistent tolerances down to ±0.01 mm, which is essential in minimally invasive surgeries where a fraction of a millimeter matters.

Challenges in Crafting Precise Micro Points — And How Rigor Excels

Producing the micro-point tip of an arthroscopy punch—where the real surgical action happens—is one of the most technically demanding stages in orthopedic instrument manufacturing. At Rigor Instruments, we treat this micro-engineering challenge as an art backed by science.

The Top Challenges in Micro-Point Manufacturing

Maintaining Edge Sharpness Without Weakening

Creating a tip sharp enough to cut soft tissue cleanly, yet strong enough not to deform or break under pressure, is a delicate balance.

Micron-Level Dimensional Accuracy

Even a 0.05 mm deviation can cause the punch to malfunction or damage surrounding tissue during surgery.

Preventing Microburr Formation

During cutting or grinding, tiny burrs may form that are invisible to the naked eye but dangerous inside a joint cavity.

Consistent Jaw Alignment

If the two jaw tips don’t meet in perfect harmony, the punch will tear tissue rather than cut cleanly.

Surface Finish and Tip Polish

The micro-point must be mirror-smooth to prevent friction, reduce trauma, and improve durability.

How Rigor Instruments Solves These Challenges

High-Speed CNC Micro-Machining

We use specialized micro-CNC tools with ultra-fine tips to carve out precise geometries down to ±0.01 mm accuracy, especially for jaw tips and curvatures.

Cryo-Treated High-Grade Steel

To ensure edge longevity and fatigue resistance, we use cryogenically stabilized medical-grade stainless steel, which minimizes microscopic distortions during machining.

Automated Burr Removal + Human Microscopy

Every punch undergoes:

Automated deburring under magnification

Followed by manual inspection under a surgical microscope to ensure zero imperfections

Jaw Calibration and Spring Tuning

After machining, each punch is hand-tuned to verify:

Tip closure precision

Smooth spring tension

Zero lateral movement

Multi-Stage Polishing & Passivation

We apply manual polishing in critical tip zones, followed by electrochemical passivation, ensuring:

Bio-compatibility

Smooth transitions

Reduced bacterial adhesion

Superior Cutting Edges

CNC machining allows for sharp, burr-free, wear-resistant edges, meaning clean cuts, less tissue trauma, and longer instrument life.

Custom Geometry

We design unique jaw angles and tip geometries for specialty procedures, ensuring that every punch is tailored for purpose and ergonomically refined.

Seamless Fit & Finish

All mechanical parts of our punches—shafts, jaws, springs—are CNC-fit to perfection, ensuring smooth articulation, zero wobble, and surgeon confidence.

Why Surgeons Trust Rigor Arthroscopy Punches

ISO 13485 Certified Production

CNC-Machined for Unparalleled Precision

100% In-House Quality Control

CE-Marked Instruments

Customization Available for OEMs & Private Labels

Real Impact in the OR

Whether you’re performing a shoulder labral repair or a knee meniscectomy, using a Rigor CNC arthroscopy punch gives you:

Clean, controlled tissue removal

Fewer instrument changes

Less fatigue from improved ergonomics

Higher success rates with lower complication risk

Partner with Rigor Instruments

We’re not just another manufacturer—we are engineering partners in surgical excellence. Our CNC facility in Sialkot, Pakistan stands as a testament to our innovation in arthroscopy instrumentation.

Let’s Build the Future of Arthroscopy Tools Together

Get in touch at 📧 [email protected] or 📞 +92 303 7759000

Let Rigor elevate your OR performance—one precision-cut punch at a time.

“You don’t become a global leader by copying others—you lead by building the future. At Rigor, we’re not just making instruments. We’re re-engineering how Pakistan manufactures them.” Ali Bhutta CEO

#ArthroscopyPunch #OrthopedicSurgery #SurgicalInstruments #RigorInstruments #CNCPrecision #MadeInPakistan #ArthroscopyTools #Meniscectomy #LabralRepair #MedicalManufacturing #MinimallyInvasiveSurgery

How Medical Devices in Pakistan Break Boundaries in Healthcare!